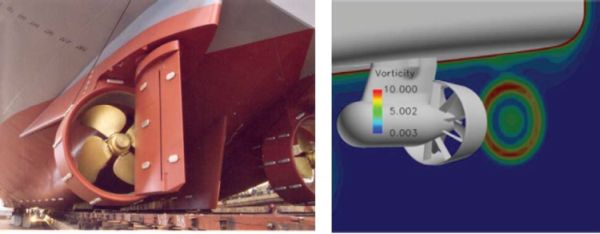

Ducted Propellers

Backgrounds

As seen so often in history, technical solutions are rapidly maturing when the need for change becomes more urgent. In this vein, the development of Energy Savings as related to ship propulsion is no different. And it is with this perspective, that the further development and implementation of Ducted Propellers on a larger scale, either with or without pre- or post-swirl stators, are regarded as an important step towards more fuel efficient ships. Currently, the propeller manufacturers within CRS produce well over 40% of all their propellers as ducted propellers. Moreover, the propellers produced for thrusters are estimated to consist of more than 90% of ducted propellers. Decreasing ship speeds and a maturing technology for pumpjets (ducted propeller with pre- or post swirl stator) are expected to increase the demand for ducted propellers.

Objectives

The objective of the current proposal is threefold:

1. Develop a BEM tool (PROCAL) and a protocol for a coupled RANS-BEM tool for analysis and design of ducted propellers. This tool should also be suitable for an analysis of bow thrusters.

2. Perform verification and validation studies with these tools.

3. Apply the tools to one or two specific design studies and demonstrate their suitability in providing design guidance.

Expected Results

1. PROCAL for ducted propellers

2. Protocol for BEM-RANS coupling for ducted propellers

3. Validation studies of methods under 1 and 2.

– Delivery of detailed data sets from CFD and experiments

4. Demonstration of design capabilities for one or two design cases.

– Two design cases: To be specified by the Working Group.