Propeller Cavitation Erosion

Backgrounds

The idea to start a cavitation erosion related project in CRS originated from the success of the EU research project EROCAV that was carried out from 2001 to 2004. Several CRS members were also member of EROCAV. The results achieved in EROCAV were significant as such, but also gave leads to further research regarding understanding the physical phenomena and developing erosion detection and prediction tools.

The ex-EROCAV members of CRS proposed a pilot project to be carried out in 2005, in order to prepare a proposal for a full CRS project to be started in 2006. The pilot project was funded by 25 k€, and indeed resulted in the start of an Erosion WG during 2006 and 2007, funded by 150 k€. The aims of the Erosion WG were to attain knowledge enhancement through observations (high speed) and acoustic emission measurements of tip-vortex related erosion on rudder horns on 3 ships, investigating the micro-structure of cavitation erosion, making review studies, performing model tests to quantify cavitation impacts and by trying to determine the energy threshold for onset of erosion by comparing ship and model scale data. For the full scale observations use was made of ships that were investigated at the same time by the CAVDISC WG, in order to economise as much as possible.

Objectives

The results of the Erosion WG were very promising, but the 2 year period and the rather limited budget were not sufficient to develop any directly applicable tools or methods for the CRS membership. A proposal to continue the erosion research was accepted by the 2007 AGM, and the Erosion 2 WG started in 2008 as a 3 year project, funded with 400 k€. The WG objectives are to avoid cavitation erosion through the development of procedures on:

- Prediction of the risk of cavitation erosion on rudders and propellers throughout the various stages of the design process, including hydrodynamic and material response aspects;

- Assessment of material response and damage rate to cavitation impacts;

- Further improvement of guidelines on propeller and rudder design.

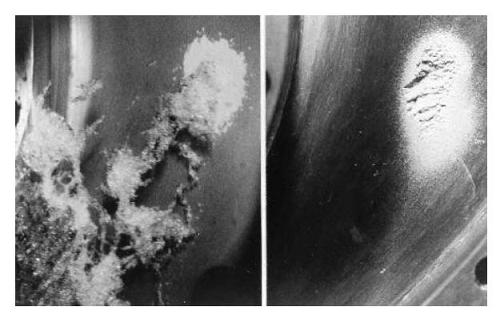

For the prediction of the risk for cavitation erosion CFD techniques are applied, which are to be validated within the project by model testing in a high speed cavitation tunnel. The material response studies are intended to provide guidance on the sensitivity of different materials to cavitation attack, as well as the effectiveness of various surface treatments and coatings to prevent or reduce erosion damage.

Expected Results

Regarding the prediction of cavitation erosion it is expected that post-processing software for CFD will be delivered to the membership. This software will enable prediction of erosion risk on the basis of CFD calculations. Within the WG no CFD is developed, but existing CFD software is applied. Guidelines will be delivered that describe how the CFD, as well as the post processing software has to be applied.

The metallurgic investigations are expected to result in guidelines for the membership that enables them to make a better selection of materials for rudders and propellers in case erosive environments are expected for a certain application. In addition the effectiveness of various surface treatments and coatings to prevent or reduce cavitation damage will be described.